I-FIT (IL – Flexibility Index Tester)

Mechanical Configuration

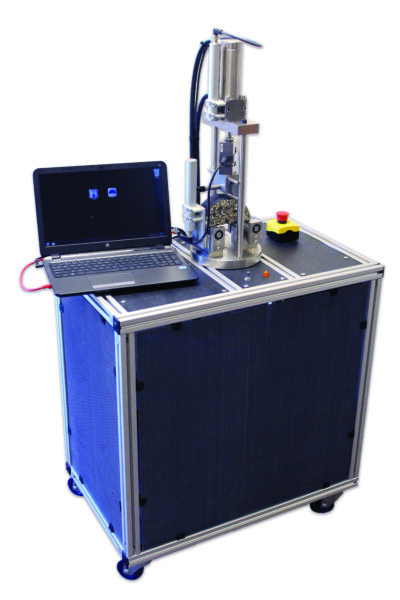

The Troxler I-FIT (Illinois – Flexibility Index Tester) machine is completely contained on a rolling portable test frame that is approximately 31.5″ L x 20″ D x 34″ H. The fixture is designed to apply load to a Semi-Circular Beam (SCB) specimen through a pivoting head and roller bearing pins. The system is designed to meet the most current standard for TP105 Illinois.

Servo Hydraulic Actuator

The system includes a 4500lbf actuator with low friction seals. It utilizes closed loop feedback from the load cell and magneto restrictive position sensors for stroke and load line displacement (LLD).

Load Line Displacement Measurement

The LLD position sensor utilizes a non-contacting method to measures displacement of SCB specimen at the loading head.

Controls and Software

It includes a custom program for I-FIT test operation. Every test has a text data file created for easy to use post processing as well as printouts from the test during operation. In addition, a Multi-Test Language (MTL) compiler is provided to allow the user to create custom programs or modify custom programs and store as a callable application.

Features

Accuracy – patented 2 CUDT system

Immediately prints and plots test summary

Includes ICT software for determining Flexibility Index (FI)

Three second runtime

Simple sample preparation

Most advanced hydraulics on the market

Specifications

| Dimensions (L xW x H) | 31.5 in x 20 in x 58.5 in |

| Weight | 350 lbs |

| Actuator Speed | 1800 in/min |

| Force | 4500 lbf |

| Stroke | 2 in or 50 mm |

| Electrical Source | 115 VAC / 20 Amp receptacle |

| Data Output | Test Advisor software or ICT software output |